Fabricating New Trolley Pole Hold Down Hooks For The Birney.

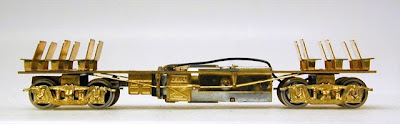

Trolley poles pointing downward is a bad thing. The hold down hooks are too short. So I'm going to fabricate some new hooks that are taller and more prototypically correct.

Trolley poles pointing downward is a bad thing. The hold down hooks are too short. So I'm going to fabricate some new hooks that are taller and more prototypically correct. Since the trolley poles are wired to the leads of the motor, the hooks need to conduct electricity from the brass body of the car to the pole. So I had to remove paint from where the hooks will be soldered to the car.

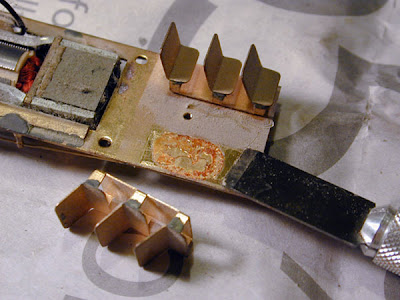

Since the trolley poles are wired to the leads of the motor, the hooks need to conduct electricity from the brass body of the car to the pole. So I had to remove paint from where the hooks will be soldered to the car. To fabricate the hold down hooks, I started with .010" x .030" brass bar stock folded in half.

To fabricate the hold down hooks, I started with .010" x .030" brass bar stock folded in half. Using a nail (I found a nail that was the same diameter of the old hook loop) I looped the brass around getting a nice curve by using pliers and a screwdriver to work the brass into shape.

Using a nail (I found a nail that was the same diameter of the old hook loop) I looped the brass around getting a nice curve by using pliers and a screwdriver to work the brass into shape. Add a reverse curve in the brass so that the apex of the loop is in line with the main shaft of the hook. Solder only the loop, the reverse curve and part of the neck together.

Add a reverse curve in the brass so that the apex of the loop is in line with the main shaft of the hook. Solder only the loop, the reverse curve and part of the neck together. Then bend the legs out and fold in the feet that will be soldered to the base. The hook assembly is now done.

Then bend the legs out and fold in the feet that will be soldered to the base. The hook assembly is now done. Solder the hook assembly to the roof boards and trim the feet. Give it a tug to confirm a good connection. Now its time to paint the hooks and while I'm at it, I'm going to right a wrong...

Solder the hook assembly to the roof boards and trim the feet. Give it a tug to confirm a good connection. Now its time to paint the hooks and while I'm at it, I'm going to right a wrong... Roof boards were never the same color as the roof. Roofs were usually of canvas or thin sheet metal, so you don't want to step on it or you'll fall right through or bend the heck out of it. So roof boards were installed so that workmen maintaining the cars could stand on the roof without damaging it. They were usually made of wood and were painted a contrasting color so the workmen could see where to step out of their peripheral vision. My hands are pretty steady, but not at this tiny scale. So I masked off around the boards.

Roof boards were never the same color as the roof. Roofs were usually of canvas or thin sheet metal, so you don't want to step on it or you'll fall right through or bend the heck out of it. So roof boards were installed so that workmen maintaining the cars could stand on the roof without damaging it. They were usually made of wood and were painted a contrasting color so the workmen could see where to step out of their peripheral vision. My hands are pretty steady, but not at this tiny scale. So I masked off around the boards. Brushed on some Scalecoat Roof Brown on the boards and painted the hooks black. Some weathering will kill the shine on the boards.

Brushed on some Scalecoat Roof Brown on the boards and painted the hooks black. Some weathering will kill the shine on the boards. Now that's more like it! The car looks much better and the horizontal poles are getting a much better electrical contact with the hooks now. Storing the car with poles on help keep the connection from oxidizing. Got to do everything you can to keep good electrical connections throughout if you want to keep them doggies rollin'. Yes sir! Keep them doggies rollin'!

Now that's more like it! The car looks much better and the horizontal poles are getting a much better electrical contact with the hooks now. Storing the car with poles on help keep the connection from oxidizing. Got to do everything you can to keep good electrical connections throughout if you want to keep them doggies rollin'. Yes sir! Keep them doggies rollin'!Dandy