Encouraged by the fantastic results Volkmar Meier has been achieving with Rapid Prototyping, Additive Manufacturing, Stereolithographic 3D Printing, I have decided to give it a go myself.

I was approached by Shapeways

years ago inviting me to try out this emerging technology of 3D

printing. Looking into it, I wasn't impressed with how rough the 3D

prints were. So I dismissed it for the time being. But the technology

has marched on and 3D prints are looking really nice these days!

Volkmar's blog, Interurban Railways, chronicles very nicely his construction of a Terre Haute, Indianapolis & Eastern wooden combine, from a 2D drawing, to a 3D render and then finally an actual 3D Print model. There is still a slight texture to the finished model, but once painted, its hardly noticeable. His work has embolden me to finally give it a try.

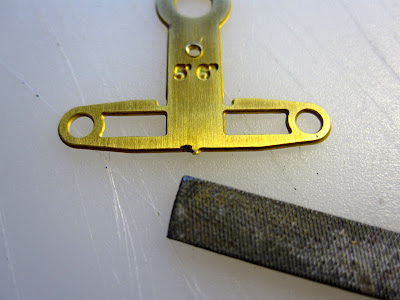

But before building something as elaborate as an interurban though, I thought I would cut my teeth on a bite-sized project first. I've been wanting to build a model of these inner city junction towers for quite some time now. I even started building one out of brass seven years ago, but the model wasn't progressing as well as I would have liked. So that project stalled. But now I think this tower would be perfect for a 3D print noob like me.

Another deciding factor is that I still have the drawings I made for the brass model. All I have to do is import these drawings into a 3D program and build the 3D model over it. There are many 3D programs out there that are well suited (and cheaper) for modeling structures for a 3D print, but I will be utilizing 3D Studio Max for this project. By profession I am an animator with years of experience animating with 3D Studio Max. So its a logical choice for me. And its already installed on my computer.

Some of the details won't print well and so have been omitted, such as the awnings and the stirrup steps. These will be added afterwards. I did include pilot holes for the stirrup steps up the post, we'll see how well they print out. The post is hollow so that wiring for lighting could be run up from the base to the tower. The roof is removable so that the interior can be painted and detailed and an occupant added (the most important part!).

There has been a flurry of discussion about 3D printing on a Yahoo Traction Modeling group lately. And after carefully weighing what folks had to say about the quality of different 3D printing companies, I have decided that since this is my first model and I want to see how much of the detail shows up on these prints, etc, I'm going to go with a company that is the least expensive but yet still has decent quality. So I put in an order with Shapeways (White Detail). When the model comes back, I'll see whats working and what isn't, make adjustments to the 3D drawing, and then place an order with an expensive, excellent quality company. Yes sir! An expensive, excellent quality company!

Dandy