Installing, Wiring, and Programing a TCS KAM4-LED Decoder.

Train Control Systems Keep Alive Decoder for LEDs.

Hot Glued the decoder to the ceiling right in the center of the car.

The wiring is pretty straight forward except that the Red wires are attached to the trolley pole bases and the Black wires to all wheels:

Red = Trolley Poles

Black = Wheels

Orange = Motor

Grey = Motor

Blue = Lighting Power Bus (positive (+) ).

White = Headlight (-)

Yellow = Rear Headlight (-)

Green = Forward Interior Lights (-)

Purple = Rear Interior Lights (-)

Programing

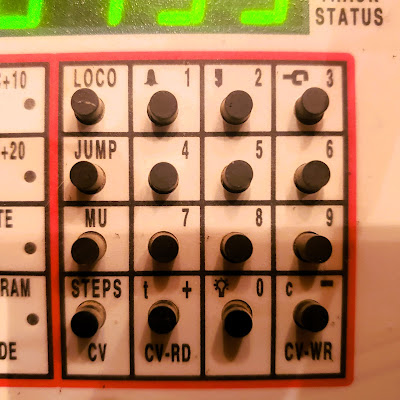

With the Digitrax Zephyr

1. Place car on the programing track.

2. Press 'Program Mode' on the Zephyr. until display reads as 'dir'.

3. Press 'LOCO' button. Display reads 'Ad2' for addresses 1-127, press again to display 'Ad4' for addresses 128-9999.

4. Press '1' and '3' and '5'. Display will read '0135'.

5. Press 'CV-WR'. Display will blink the 'Ad#' and then '0135'.

6. Return the car to the mainline to test it.

Some CV's need to be changed. The Green wire (forward interior lights) defaults to the Function 1 (F1) button which is fine. But the Purple wire (rear interior lights) defaults to the F2 button which is a momentary contact button normally used for locomotive whistles (the whistle sounds when the button is held down). Which means that the interior lights on car #135 only light when the button is held down. So the purple wire needs to be remapped to the F3 button instead.

Digitrax Zephyr Function buttons.

I need to remap the Green wire (CV 35) from function button 2 (F2) to function button 3 (F3).

Green wire (CV 35) = Front Purple wire (CV 36) = Rear.

To remap the button-

Program: CV 35 V=4 (simply confirm this value since this is the default)

CV 36 V=16 (from the default value of 8)

Remapping CV's is easiest using JMRI Decoder Pro

Otherwise its button mashing on the Zephyr:

1. Place car on the programing track.

2. Activate 'Program Mode' on the Zephyr. Program Mode light lights up.

3. Press the 'CV' button. Display reads 'ad2' or 'ad4'.

4. Press '3' and '6'. Display reads '0036'.

5. Press the 'CV' button again. Display still reads '0036'.

6. Press '1' and '6'. Display reads the value of '0016'.

7. Press the 'CV-WR' button. Display should blink once as it writes to the decoder.

8. Return the car to the mainline to test it.

Yes sir!

That oughta do it!

Dandy