I have no idea how I'm going to do this. So, as usual, I'm just going to have to take it one step at a time. Yessir! One step at a time.

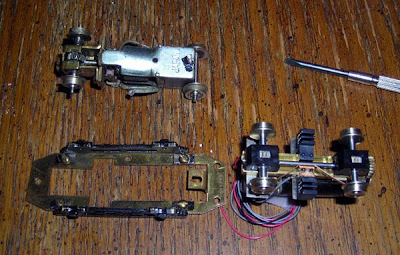

I have no idea how I'm going to do this. So, as usual, I'm just going to have to take it one step at a time. Yessir! One step at a time. The first order of business is to remove the old motor and see how the Bullant relates to the frame. First off, its apparent that the Bullant will not slip right in. The wheels prevent dropping in the mechanism down from the top, and the bolsters prevent it from coming up from the bottom. So somethings got to give.

The first order of business is to remove the old motor and see how the Bullant relates to the frame. First off, its apparent that the Bullant will not slip right in. The wheels prevent dropping in the mechanism down from the top, and the bolsters prevent it from coming up from the bottom. So somethings got to give. Looks like I have four choices at how to do this. 1- build a new frame, as Bruce Battles of Menlo Park, CA seems to have done with this single truck streetcar ( I don't know Bruce or how to contact him, If anyone knows this guy, I sure would like to correspond with him about his modeling, and probably ask permission to use above photo ~ eep!). Or 2- modify the existing frame. Or 3- mount the Bullant directly to the Birney shell. Or 4 – glue the truck side-frames to the polystyrene side-frame supports on the Bullant, and then mount the side-frames to the trolley body.

Looks like I have four choices at how to do this. 1- build a new frame, as Bruce Battles of Menlo Park, CA seems to have done with this single truck streetcar ( I don't know Bruce or how to contact him, If anyone knows this guy, I sure would like to correspond with him about his modeling, and probably ask permission to use above photo ~ eep!). Or 2- modify the existing frame. Or 3- mount the Bullant directly to the Birney shell. Or 4 – glue the truck side-frames to the polystyrene side-frame supports on the Bullant, and then mount the side-frames to the trolley body.

As you can (barely) make out in this photo, the mounting bolsters of the Bullant are actually higher than the top of the chassis frame. So options 3 and 4 are out. But if I could just slide in the Bullant into the chassis frame, then the mounting bolsters could be mounted from the top.

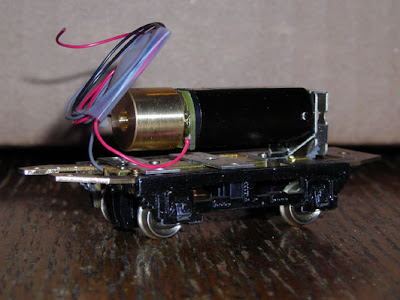

As you can (barely) make out in this photo, the mounting bolsters of the Bullant are actually higher than the top of the chassis frame. So options 3 and 4 are out. But if I could just slide in the Bullant into the chassis frame, then the mounting bolsters could be mounted from the top. So as you can see, I decided to modify the frame (Option 2). If I mess it up, then I'll simply build a new frame (Option 1). I cut a piece of the frame out so that the Bullant could just slide in. This kind of compromises the integrity of the frame, but note that the mounting holes are on either side of the cut, so when bolted in place on the Birney body, things will be rigid again.

So as you can see, I decided to modify the frame (Option 2). If I mess it up, then I'll simply build a new frame (Option 1). I cut a piece of the frame out so that the Bullant could just slide in. This kind of compromises the integrity of the frame, but note that the mounting holes are on either side of the cut, so when bolted in place on the Birney body, things will be rigid again. Whoops! Things are sitting kind of high. The Birney body needs to sit lower so that the center of the side-frames are equal to the center of the wheels. More fiddling needs to be done. But we're getting there Huh? The Bullant is in there!

Whoops! Things are sitting kind of high. The Birney body needs to sit lower so that the center of the side-frames are equal to the center of the wheels. More fiddling needs to be done. But we're getting there Huh? The Bullant is in there!

Spacers between the frame and the bolsters will raise the Bullant / lower the Birney body, so I

cut some from brass stock and soldered them to the frame. Now this is funny; I wanted to screw the Bullant to the spacers so the Bullant could be removed from the frame. But while I was trying to center the mounting holes so I could mark their location for drilling, things kept sliding around. So I temporarily super glued the Bullant in place. Well, the super glue has worked so well, I think I'll just go with it for a while. Yessir! Just go with it for a while!

cut some from brass stock and soldered them to the frame. Now this is funny; I wanted to screw the Bullant to the spacers so the Bullant could be removed from the frame. But while I was trying to center the mounting holes so I could mark their location for drilling, things kept sliding around. So I temporarily super glued the Bullant in place. Well, the super glue has worked so well, I think I'll just go with it for a while. Yessir! Just go with it for a while!

I did it! I actually pulled it off! The Bullant is in there, and its in there solid! I'm just so proud of myself. I wish I could test it. What I need to do now is build a test track. Yessir! I need to build a test track!

Dandy