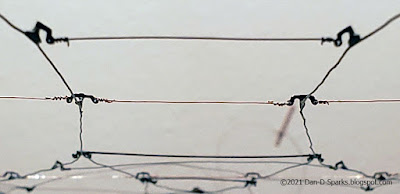

Successfully Strung a Span Wire Between Two Electroliers - Without Blowing out the Lamps!

This is a big relief since the brass Electroliers are ground for the 3 volt DC streetlamps AND act as an anchor for the 15 volt AC overhead.

The fear being that the 3 volt LEDs are exposed to the 15 volts running current. But since each have their own power source it doesn't seem to be a problem.

Now that all of the Electroliers are in I would really like to install the span wires between them. The overhead in the intersection is a bit bouncy without them. After the success of a little test rig I have commenced stringing the span wires.

These old wooden temporary poles and span wires can finally be removed. The poles were on the building property line and with them gone now, I can finally get to building the buildings.

Trying something new here. The rule has been Nickle Silver wire for the contact wire and Phosphor Bronze for the span and pulloff wires. But for these new span wires I'm trying 30 AWG High Quality Polyurethane Enameled Copper Wire. This wire is softer and much easier to work with. The phosphor bronze I was using just loves to pierce the skin!

Hmmm... seeing my wire wrappings up close in photographs I see that my wrappings are kind of loose. I need to work on tightening my wire wrapping skills.

Yes sir! Tighten my wire wrapping skills.

Dandy

That first photo looks great. Looks a bit like a snowy winters day, grey cloudy sky....

ReplyDeleteThanks, I thought so too. It looks to me when the marine layer rolls in from the ocean and things get misty and cold.

DeleteOh ! Yes, exactly !

DeleteYes, copper wire is nicer to work with than phosphor bronze, and just as adequate for most purposes. You may find, though, that the copper wire tends to stretch a little over time. That's no problem if you incorporate a way to tighten your span wires, should the need arise. It all looks great!

ReplyDeleteIt stretches?! I'll have to keep an eye out for that. Thanks Rob!

Delete